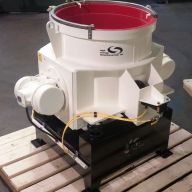

High Frequency Finisher

CLM Vibetech, Inc. high frequency finishers feature an innovative, professionally engineered design with an exceptionally high-quality output. They allow for delicate, sensitive more complex parts, which have traditionally been finished manually, to now receive an automated vibratory finish, which creates labor efficiencies and enhanced part quality. Finally, their small footprint optimizes floor space. Contact us to learn more today!