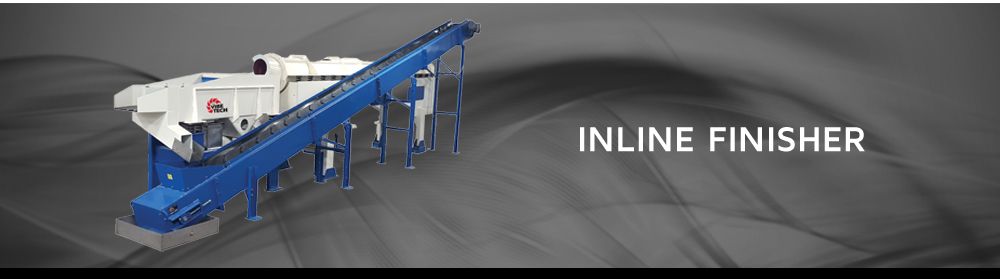

Inline Finisher

Inline finishers feature an innovative engineered design with an exceptionally high-quality output. They allow for large parts and fabrications, which have traditionally been finished manually, to now be placed into a larger process chamber and receive an automated vibratory finish, which decreases consumption costs. This process also frees up time for operators to focus on other key duties, which provides labor efficiencies to the company. Although standard vibratory units can be automated, few can be completely hands-off during the finishing process. Continuous style finishers provide that capability. Additionally, the larger channel width allows for increased capacity, which streamlines the finishing process and makes future growth more attainable. Finally, an inline finisher process helps achieve a higher level of operator safety and consistency to quality for the desired result of the finished product. All of these features add up to provide the most structurally sound and flexible system on the market. Similar to an assembly line, there is no better machine for dollar value than the CLM Vibetech, Inc. inline finisher.